Have you ever wondered how smartphones are made, what stages it goes through, how many people are involved in the process? The answer to this is given by Meizu with its Open Day on September 3, 2017, allowing consumers to peek into the research laboratory of the company.

The production of technological gadgets is a long and laborious process, where the quality of the final product depends on many factors. To avoid defects, defects, engineering errors and other problems, each company must do a thorough testing of its devices, using the latest equipment that meets world standards.

Most not only Chinese but also world manufacturers do not have their own laboratories and give their products for testing to external companies. Meizu was one of the first Chinese companies to realize how important it is to independently control the entire process of production and testing of smartphones, and made MEIZU LAB.

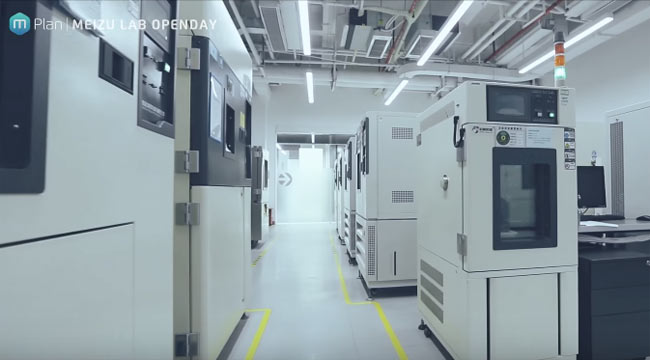

MEIZU LAB was established in 2006 and has an investment of about $15 million. The laboratory is located in the building where the company is headquartered, covers an area of 2000 square meters and consists of 12 sites in 6 different categories. They employ more than 150 staff members, using 280 inspection devices. In MEIZU LAB 600 phones can be tested at once.

It is important to note that MEIZU LAB is ISO 17025 certified by the Chinese National Accreditation Assessment Service (CNAS). ISO/IEC 17025 is a quality management standard in testing and calibration laboratories. Meizu is currently the second largest manufacturer in China with its own ISO 17025 certified laboratory.

For example, the internationally recognized ETS Lindgren AMS-8923 system, the so-called microwave dark room, is used to test the antenna quality in the flagship Meizu PRO 7. It checks how well the radio components of the smartphone work. This system costs in the order of $1.5 million.

The ACQUA electro-acoustic tone-sound testing system, which costs about $ 600,000, is used to test the audio. It can measure and analyze the electroacoustic characteristics of communication products and voice quality in various background noises.

MEIZU LAB also checks the physical properties of smartphones – durability and strength of the case, the life of the physical buttons, the quality of the case, the battery life cycle, power consumption and much more. Drop tests are also performed, during which the phones are tested in different scenarios of falling on different parts of the body and from different heights.

See also the video from the walk around MEIZU LAB from the Open Day:

FAN CLUB BULGARIA

FAN CLUB BULGARIA Meizu Lucky 08: A budget AI phone with flagship features

Meizu Lucky 08: A budget AI phone with flagship features Meizu Lucky 08, most powerful AI phone in the 2,000 yuan range, will be released this month

Meizu Lucky 08, most powerful AI phone in the 2,000 yuan range, will be released this month Meizu 20, Meizu 20 PRO, Meizu 20 INFINITY and Meizu 21 PRO won Red Dot Award 2024

Meizu 20, Meizu 20 PRO, Meizu 20 INFINITY and Meizu 21 PRO won Red Dot Award 2024